Laura Zhang

Sales & Marketing,HJT EXPO

| Phone | +86 10 58677126 |

|---|---|

| Fax | +86 10 58677126 |

| wenting.zhang@interfoam.cn | |

| Address | Rm 2003, Building A,Timecourt, Chaoyang District, Beijing, China |

The rapid growth of cloud computing, big data, 5G, IoT, mobility and automation applications is driving advanced semiconductor manufacturing technologies to break the limit.

Generally, semiconductor devices require nanometer-level flatness, otherwise the resistance value will be uneven, and the photolithography will be inaccurate. International leading chip manufacturers have adopted 5 nm lithography process.

Chemical Mechanical Polishing (CMP) is currently the only technology capable of achieving both overall and partial planarization, enabling chipmakers to further reduce circuit areas and improve the performance of lithography tools. For polishing process, the two most crucial materials are polishing liquid and polishing pads.

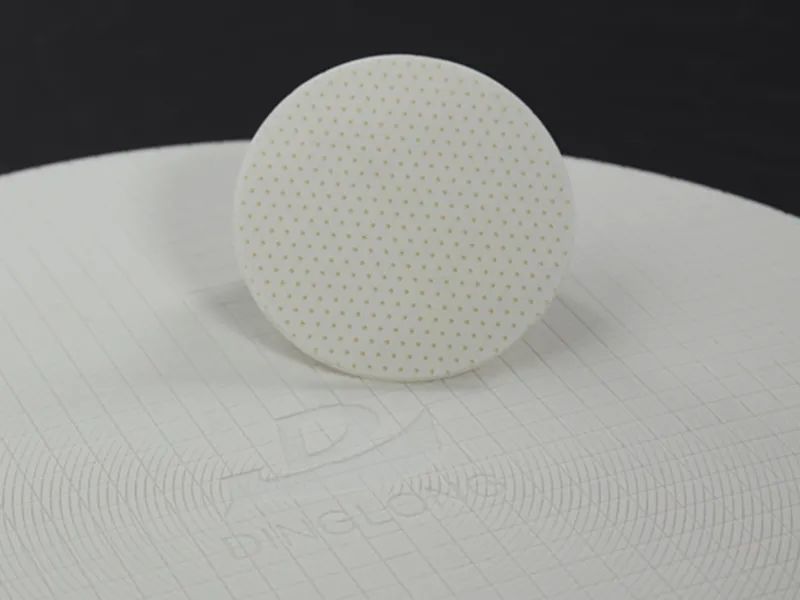

CMP polymer polishing pads have good corrosion resistance, hydrophilicity and mechanical properties. As one of the major types of CMP polishing pads, polymer polishing pads are mainly made of foam-cured polyurethane, which can meet the strict requirements of CMP process and specific applications.

During polishing process, the surface micropores (mechanical properties and porous water absorption properties) of rigid polyurethane foam pads can soften and roughen the pad surface, and retain abrasive particles in the polishing liquid. The main models include IC1000, IC1400, IC2000, SUBAIV, etc., among which, IC1000 and SUBAIV are the most widely used.

The Solid State Microcellular Foaming (SSMF) process is adopted to produce porous chemical mechanical polishing pads with a wide range of pore sizes and porosity. During the basic process, thermoplastic polyurethane (TPU) with various resin hardness is used, and by controlling the pore size, porosity, and pad hardness, CMP pads with adjustable performance can be customized.

This solution makes a breakthrough in balancing high removal rate, planarization, and low defectivity, and is able to provide improved texture during use to achieve higher removal rate and performance stability.

Dow Chemical Company dominates the global market of polishing pads, accounting for 79% of the global market share. Five major manufactures in the United States and Japan occupy 91%.

According to statistics from various markets, the global market value of CMP pads in 2022 is expected to reach USD 5.225 billion. At present, this value is estimated to be USD 878 million, and the Chinese market is valued at around 2 billion RMB.

In the future, China will witness the fastest growth in the Asia-Pacific region.

——————————————————————————————————————————————————

Interfoam China is a professional exhibition for the whole foam industrial chain in Asia, and is an international event that cannot be missed by the professionals from foam industry all around the world.

Interfoam China focuses on the latest production, technology & equipment, new techniques, new trend, and new application in foam industry, and spare no effort to provide a professional platform integrating technologies, trade, brand display, and academic exchanges for its upstream and downstream as well as vertical application industries, thus promoting industrial sustainability.

Sales & Marketing,HJT EXPO

| Phone | +86 10 58677126 |

|---|---|

| Fax | +86 10 58677126 |

| wenting.zhang@interfoam.cn | |

| Address | Rm 2003, Building A,Timecourt, Chaoyang District, Beijing, China |

Please browse vertically for better experience.