The switch to electric mobility is gathering pace and as energy technologies become more advanced, so do the challenges for vehicle manufacturers. For example, silencing efforts have shifted from the powertrain to road and wind noise, while batteries have specific needs in terms of thermal management. As a long-established partner of the automotive sector, we are committed to giving our customers what they need to stay ahead.

电动出行的时代变革正在加速推进,伴随能源技术的持续迭代升级,汽车制造商面临的挑战亦呈现动态演变。例如,车辆降噪的核心焦点已从动力系统转移至道路与风噪,而电池对于热管理的需求愈发严苛。作为深耕汽车行业的长期合作伙伴,我们致力于为客户量身定制契合未来发展的产品,并提供全方位的技术支持,助力客户稳居行业潮头。

产业演进中

的经验价值 The value of experience in an evolving industry

Carpenter has been investigating and developing solutions for batteries since the early days of electromobility and has extensive knowledge of the technologies as well as market trends. A key consideration in today’s industry is the lack of standardisation. Battery design is still evolving to increase energy density and lifetime, reduce costs and shorten charging times. And as battery technologies develop, so do the demands on every component within and around the battery pack.

自电动汽车发展初期,可彭特(Carpenter)便投身于电池解决方案的探索与研发,积累了深厚的技术底蕴,并深入了解行业的发展趋势。当今行业发展面临一大核心挑战在于标准化体系的缺失,电池设计仍在持续迭代升级以提升能量密度和延长使用寿命、降低成本并缩短充电时间。值得注意的是,伴随电池技术的不断革新,对电池包内外各组件的性能要求亦同步升级。

The breadth of our materials portfolio and processing capabilities adds significant value in this regard. Our materials range spans foams (PU, PE, EPDM, silicone), facings (PU film, non-woven, etc.), fibres (PET, PU, etc.) and adhesives. We are also highly experienced in combining these to achieve specific results, applying advanced in-house processing capabilities in cutting, lamination, spooling and thermocompression.

在此背景下,我们丰富多元的材料产品矩阵与卓越的加工能力展现出无可比拟的价值。我们的材料体系涵盖发泡材料(聚氨酯、聚乙烯、三元乙丙橡胶、有机硅)、覆面材料(聚氨酯薄膜、无纺布等)、纤维材料(聚酯、聚氨酯等)以及胶粘剂。我们高度精通灵活组合各类材料特性,并通过内部先进的切割、复合、绕卷、热压等加工工艺,精准达成客户所需的特定性能。

This gives our engineers the flexibility to develop solutions quickly and meet new needs as they emerge. In the absence of industry standards for battery design, we take a tailored approach, differentiating on the basis of battery cell chemistry, design, format, integration and thermal control technology.

依托强大的技术实力与丰富的材料资源,我们的工程师团队能够快速响应市场变化,灵活开发创新解决方案,及时满足行业不断涌现的新需求。鉴于电池设计尚未无行业标准,我们针对电池电芯化学体系、设计方案、规格尺寸、集成方式及热控技术等差异化需求,量身定制专属解决方案。

电动汽车

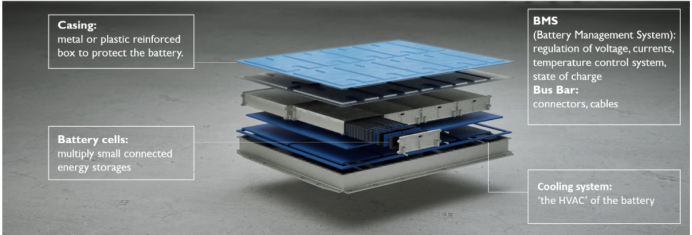

电池核心组件 The main components of an EV battery

The battery pack: an extreme environment

From full plug-in battery electric vehicles (BEV) to different hybrid variants (PHEV, HEV and MHEV), all electric vehicles have one requirement in common. The battery cell and pack need protection that can withstand extreme conditions. The challenges include heat, expansion and contraction created by the electrical current inside the battery cell, and thermal runaway. The optimal temperature for battery cell performance is 40°C, and materials used in the battery pack must be able to work with the manufacturer’s cooling systems for the most efficient thermal management.

无论是全插电式纯电动汽车(BEV),还是各种混合动力车型(PHEV、HEV和MHEV),电池系统是所有电动汽车的共同核心命脉。电池电芯和电池组需要具备强大的防护能力以抵御严苛环境的考验。这些考验包括内部电流产生的热量积聚、电芯膨胀收缩,以及潜在的热失控风险。电池电芯发挥最佳性能的温度是40 °C,因此,电池组选用的材料不仅要适配制造商的冷却系统,更需协同构建高效热管理体系。

电动汽车

电池产品矩阵 A portfolio dedicated to EV batteries

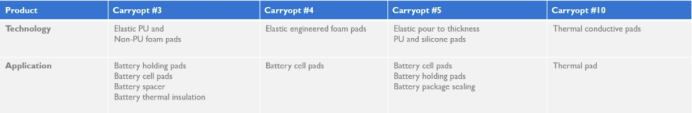

As well as thermal control solutions for every cooling system, we provide purpose-designed pads and materials to protect, seal and thermally insulate the battery cells and battery pack. Our Carryopt product lines are engineered for optimal carrying and support of battery components. They are available in different variants to meet specific requirements in terms of hardness, compression set, electrical resistance, flame behaviour, vibration isolation, price/performance ratio and more.

我们不仅为全类型冷却系统定制热管理解决方案,更研发了专业级垫片与材料,从密封防护到高效隔热,全方位守护电池电芯与电池组安全运行。我们的Carryopt系列产品以精密设计为核心,为电池组件提供稳定可靠的承载与支撑方案。该系列具备多元产品形态,精准匹配客户在硬度调控、压缩性能、电阻参数、阻燃标准、振动缓冲及性价比等维度的个性化需求。

缔造移动出行

的未来 Creating the future of mobility

In addition to EV battery applications, we support manufacturers with forward-thinking solutions for: electric motor encapsulation, HVAC sealing and insulation, power inverter insulation, side fender seals, silent tyre and wheel arch acoustic pads.

我们的创新步伐不止于电动汽车电池领域。凭借前瞻性技术布局,我们还为制造商提供覆盖多场景的解决方案:从电动机的高效封装、暖通空调系统的密封隔热,到功率逆变器绝缘防护;从侧挡泥板的密封优化,到静音轮胎与挡泥板隔音板等。

我们在全球设有十个创新中心,致力于通过创新创造更美好的社会。我们的资源包括三家声学中心、四个内部试制线和4000 多个专有配方,同时与知名大学和技术专家长期保持宝贵的合作伙伴关系。