More News

UT Dallas Chemists Create Self-Repairing, 3D-Printed Foam That’s Made to Flex and Last

Industry news

The lightweight, recyclable material can be printed into complex shapes—including a balloon dog—and shows potential for use in helmets, insulation, and more. The research explores a method still largely untapped in commercial manufacturing.

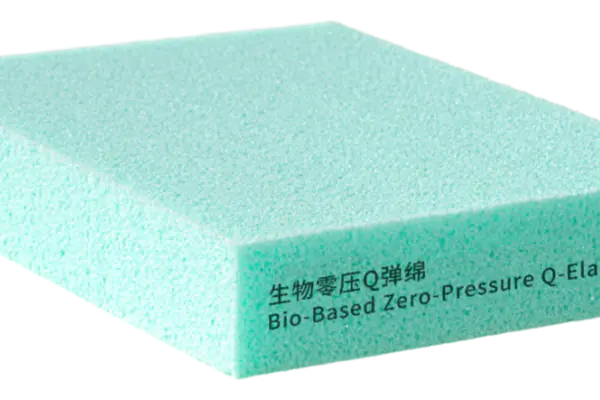

Zhejiang Xingpai: Supercritical Foaming+High-performance Materials Drive Industry Green Upgrading - Interfoam Exhibitor Star Power

Industry news

Zhejiang Xingpai New Materials Co., Ltd. is a technology innovation enterprise jointly invested by Huamao (Xiamen) New Materials Technology Co., Ltd. (stock code: 603306. SH), focusing on the research and industrial application of supercritical physical foaming technology for a long time.

Announcement of Invited Guests for Interfoam Particle Foam Forum: Fei Wu, Kayla Zheng (EPP), Martin Frühauf (EPS), Wentao Zhai, Kayla Zheng (IR), Martin Frühauf (E-TPU).

Exhibtion news

Particle foaming technology uses pre foaming, curing, and molding techniques to expand and fuse polymer particles, forming foam materials and products with lightweight, high-strength, cushioning, and thermal insulation properties. It is widely used in packaging, automotive, home appliances, sports and leisure industries.

Nanfang Rubber and Plastics: Driving a New Trend in the Rubber and Plastics Industry with Innovative Silicone Extrusion Products - Interfoam Exhibition Star Power

Industry news

Since its establishment in 1986, Foshan Nanfang Rubber&Plastic Co., Ltd. has been deeply involved in the field of silicone foam, experiencing and participating in the magnificent process of China's reform and opening up and industrial takeoff, witnessing and assisting the rise and upgrading of "Made in China" along the way.

Changhua Chemical: Empowering the Green Upgrade and Comfortable Experience Innovation of Polyurethane Industry with Polyether Core Technology - Interfoam Exhibition Star Power

Industry news

Changhua Chemical Technology Co., Ltd. (stock code: 301518) is a holding subsidiary of Jiangsu Changshun Group Co., Ltd. It was established in 2010 and listed on the Growth Enterprise Market of the Shenzhen Stock Exchange in 2023.

Dongya New Materials: A Revolutionary Journey of Supercritical Foam Materials and Multi Performance Sole Solutions - Interfoam Exhibitors Star Force

Industry news

Nanjing Dongya High-Tech Materials Co., Ltd. was founded in 1994 and is located at No. 10 Xingzhuang Road, Nanqu District, Lishui Economic Development Zone, Nanjing City, Jiangsu Province. It is a high-tech material sole research and production enterprise that integrates research and development with large-scale production.

Cutting Equipment Maker-Guangdong Zhende Intelligent Equipment Co., Ltd.-Interfoam 2025 Exhibitor New Star Power

Industry news

Dongguan Zhende Precision Machinery Industry Co., Ltd. was established in 2009 and is a high.tech enterprise that integrates research and development, design, manufacturing, and sales.

Announcement of Invited Guests for Interfoam Shoe Material Foaming Technology Forum: Zhenxiu Zhang, Dahai Yu , Gengda Deng , Zhengang Liao , Hanqiao Zhang

Industry news

Foaming technology has made a key contribution to shoe performance. In order to meet market demand and promote innovation in foamed shoe materials, this sub forum on shoe material foaming technology will mainly focus on direct injection molding foaming technology, supercritical foaming technology, 3D printing foaming technology, sustainable foaming materials and other directions for discussion.

Korean Enterprise AFC: EPDM rubber foam material manufacturer - Interfoam exhibitor Star Force

Industry news

AFC manufactures 'EPDM rubber' in 'open cell' and 'closed cell',as well as CR rubber.

Upon request, EPDM order can be placed in 'roll' or 'sheet' types, according to your needs.